1. Powder Spraying Oven Manufacturers Equipment Overview

Leading Powder Spraying Oven Manufacturers produce industrial-grade curing systems with insulated chambers, heating elements (electric, gas, infrared), precision temperature controls, and conveyor integration. Premium models feature multi-zone heating (±2°C accuracy), IoT-enabled diagnostics, and energy recovery modules. Powder Spraying Oven Manufacturers like Grieve and Wisconsin Oven prioritize stainless steel construction for durability and compliance with NFPA 86 safety standards.

2. Applications of Powder Spraying Oven Manufacturers

Ovens from top manufacturers cure coatings in automotive (body panels), aerospace (engine parts), appliances (refrigerators), and architectural industries (steel beams). They also serve niche markets like medical devices (antibacterial coatings) and renewable energy (solar panel frames). Customizable designs accommodate batch or continuous production lines.

3. Pricing from Powder Spraying Oven Manufacturers

Standard batch ovens cost 10,000–50,000, while conveyorized systems range from 80,000–300,000. High-capacity ovens with advanced features (e.g., AI temperature control) exceed $500,000. Prices vary by size (5–50 m³), heating technology, and energy efficiency ratings (e.g., ENERGY STAR certification).

4. Operating Powder Spraying Ovens Correctly

Preheating: Allow 30–60 minutes to stabilize temperatures.

Loading: Space parts evenly to ensure uniform airflow.

Curing: Follow powder specs (typically 180–220°C for 10–30 minutes).

Maintenance: Clean burners monthly and replace heating coils every 2–3 years.

5. How to Choose Powder Spraying Oven Manufacturers

Certifications: Prioritize manufacturers with ISO 9001, CE, and OSHA compliance.

Energy Efficiency: Opt for ovens with heat recovery systems (30%+ energy savings).

Customization: Select manufacturers offering modular designs for future scalability.

Support: Ensure access to 24/7 technical service and spare parts.

6. Safety Protocols from Powder Spraying Oven Manufacturers

Ventilation: Install explosion-proof exhaust systems to remove fumes.

Thermal Protection: Use heat-resistant gloves and aprons during operation.

Fire Safety: Integrate CO2 suppression systems and thermal fuses.

Training: Enforce lockout/tagout procedures during maintenance.

7. Design Advantages of Top-Tier Manufacturers

Leading manufacturers design ovens with ceramic fiber insulation (reducing heat loss by 40%), touchscreen HMIs for real-time adjustments, and predictive maintenance algorithms. Modular panels allow easy expansion, while dual-fuel capability (gas/electric) ensures operational flexibility.

8. FAQs on Powder Spraying Oven Manufacturers

Q: How do manufacturers ensure temperature uniformity in ovens?

A: Multi-zone heating and recirculating fans maintain ±2°C variance across the chamber.

Q: Can powder spraying oven manufacturers customize sizes?

A: Yes, most offer bespoke designs for parts up to 20 meters long.

Q: What maintenance prolongs oven lifespan?

A: Clean air filters monthly and calibrate sensors annually per manufacturer guidelines.

Q: Are eco-friendly ovens available from manufacturers?

A: Yes, energy-efficient models with heat recovery meet EPA and REACH standards.

Q: How to verify manufacturer reliability?

A: Check client testimonials, industry certifications, and warranty terms (e.g., 5-year coverage).

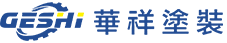

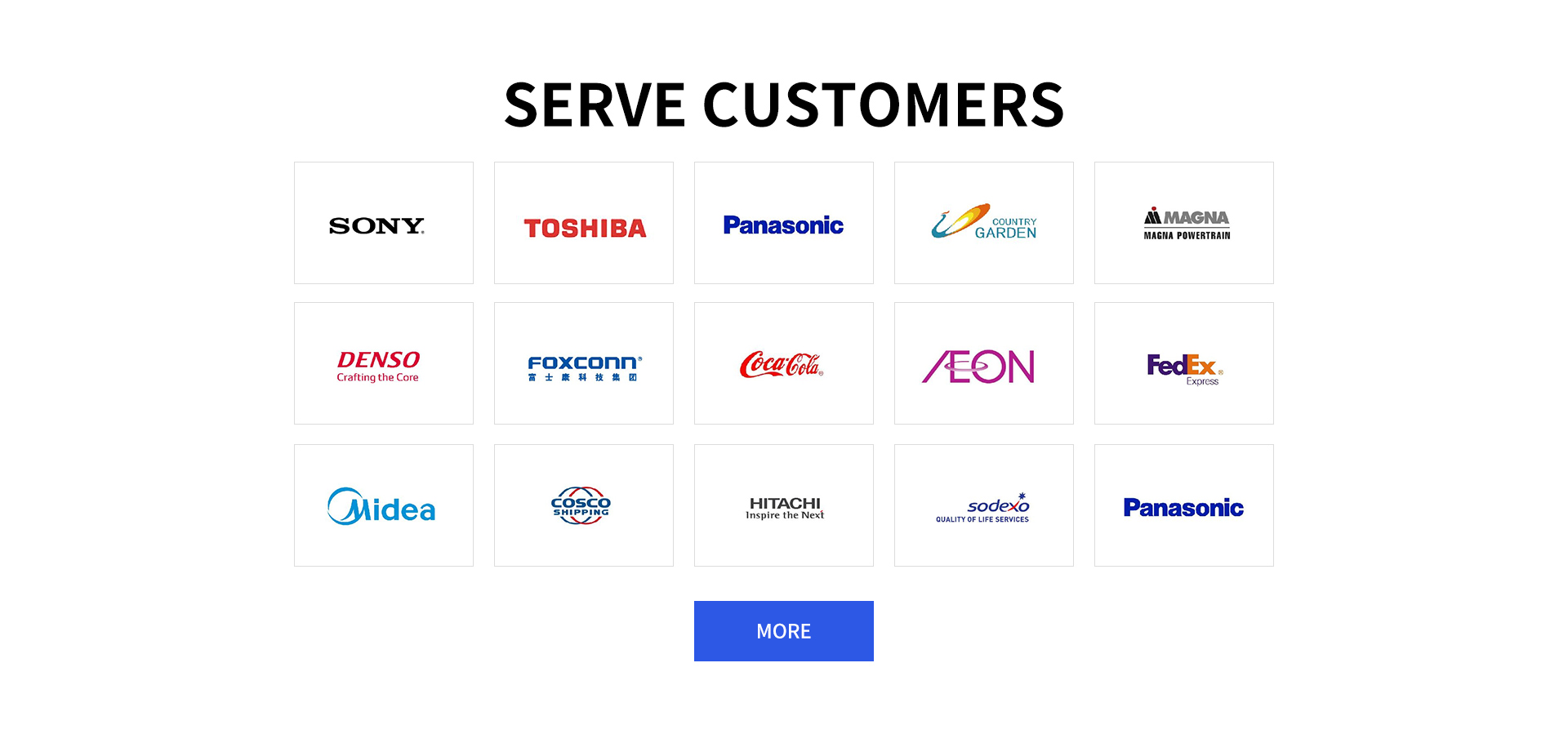

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com